We develop bare-metal C firmware for embedded systems where deterministic behavior and long-term reliability matter. Our work includes board bring-up, custom SPI, I²C, and UART drivers, and low-level system integration on platforms such as MSP430, NXP Kinetis (K64), and ARM Cortex-M microcontrollers.

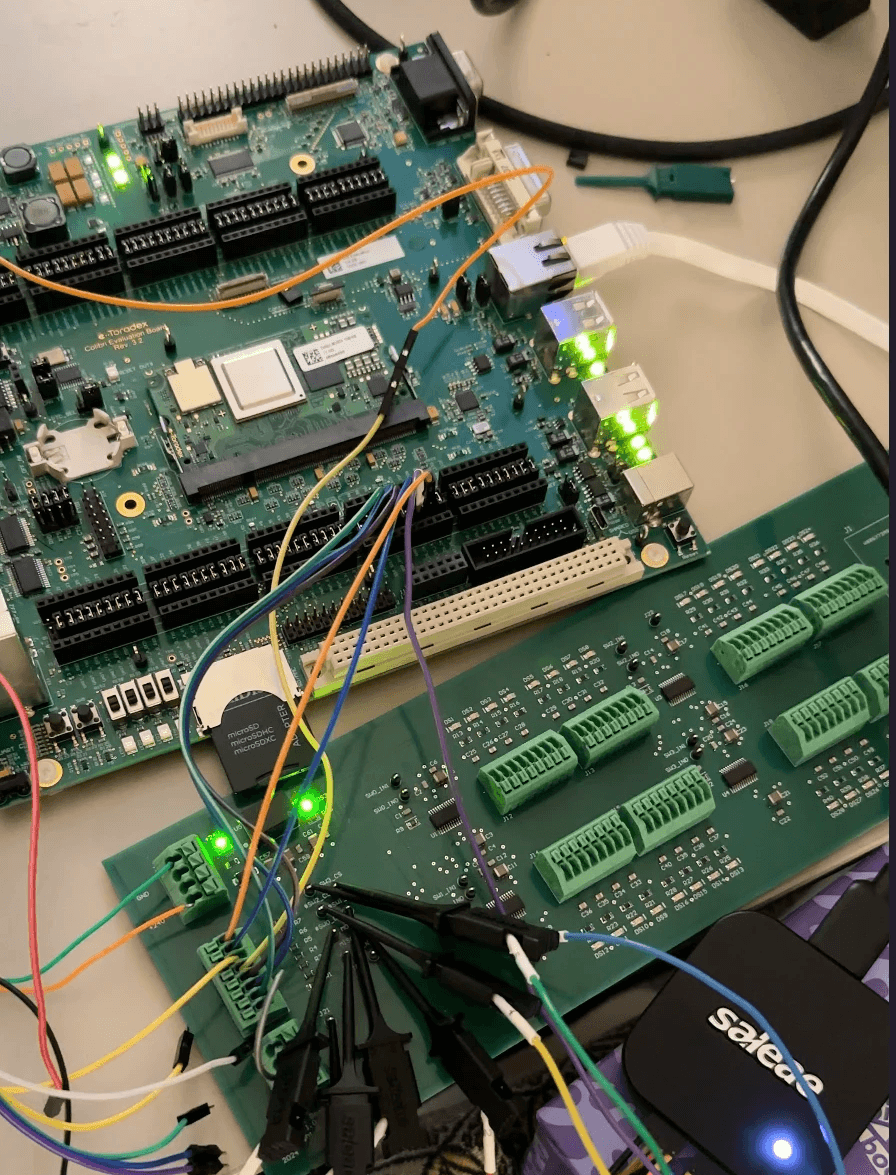

We work close to the hardware, using JTAG/SWD, logic analyzers, and oscilloscopes to debug timing issues, communication faults, and hardware–firmware interactions—particularly when problems only appear under real load or environmental stress.

From first power-up through production-ready firmware, our focus is on systems that boot cleanly, communicate predictably, and continue working in the field.

We design and validate custom hardware for embedded systems where reliability, power efficiency, and real-world performance matter. Our work includes schematic design and PCB layout for controllers and sensor platforms with strict requirements around power consumption, signal integrity, and durability.

We have deep experience in low-power analog and digital design, including battery-powered systems intended to operate for months or years. This includes power-domain optimization, component selection for low leakage, and hardware support for effective sleep and wake strategies.

For more demanding environments, we design hardware with resilience in mind—addressing signal conditioning, EMI mitigation, overvoltage protection, and fault-tolerant communication paths where appropriate.

We validate designs using oscilloscopes, logic analyzers, and bench instrumentation to confirm timing, signal quality, and edge-case behavior. Our goal is hardware that performs reliably in the field, not just in simulation.

We also support compliance-driven development, including RoHS, CE, and FCC Class B considerations. From creepage and clearance practices to ESD and EMI mitigation, we help prepare designs for self-declaration and lab certification, including pre-compliance testing and iterative fixes to reduce risk before formal testing.

We build software systems that integrate tightly with embedded hardware to support development, testing, and deployment. This includes automating lab equipment, managing embedded devices, and collecting or visualizing real-time data in a way that’s practical to maintain and scale.

Our tooling is primarily Python-based, with support for Modbus, serial protocols, and custom device interfaces. We develop lightweight utilities and interfaces to bring hardware online quickly—ranging from simple Tkinter tools to Flask-based dashboards and headless automation, depending on the task and deployment environment.

To ensure reproducibility across systems, we containerize applications using Docker. Our deployments are structured for modularity, secure communication, and portability across development machines, test stations, and remote units.

We also design systems for automated data collection, control logic, and test orchestration. From calibration rigs to distributed monitoring setups, we help teams replace fragile scripts and manual workflows with reliable, repeatable tooling.